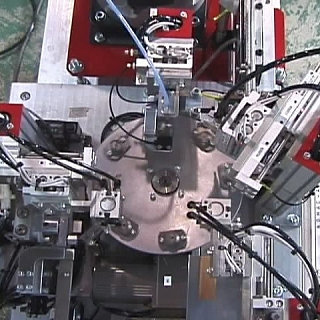

Ballpoint pen tip assembly machine

TOSCO ABS-01

Features

TOSCO ABS-01 is a full-automatic assembly machine. processes such as inserting a spring into ballpoint pen tip and jointing plastic pipe, etc. can be done as desired. Total accumulated to 80 units. It has been widely used by the users in ballpoint pen manufacturers worldwide.

TOSCO ABS-01 is commonly equipped with 8 pallets to carry out following 4 processes.

|

|

|

|

(Note) Process 3 can be changed to “Swage the tip”

Effective when used along with TOSCO C1-TIP

Tangle prevention function

Springs made by the model TOSCO C1-TIP (Spring Coiling Machine for ballpoint pen tip) have a complicated shape with fold-back end. So at the time of transferring them to the next process, it brings some trouble to keep individual springs separated.

TOSCO ABS-01 is designed to carry the spring made by TOSCO C1-TIP and directly insert it to the tip without having any linking processes like stockers. It totally saves troubles in midway storage.

The interlock function from the combination of TOSCO C-1 and TOSCO ABS-01 is as under.

- TOSCO C1-TIP finishes machining a spring. At the last process, cutting bite chops off the spring

- Chopped spring is carried through the air shooter to ABS-01. And ABS-01 automatically inserts the spring as per process 2.

- Photoelectric sensor confirms that the spring was inserted, and the signal from the sensor rotates the rotary table (commonly 45 degrees for 8 pallets).

- After rotary table is rotated, ABS-01 starts the processes of 1, 3 and 4.

- C1-TIP finishes its spring-forming process and is at stand-by position waiting to chop off the spring. When receiving a signal from the photoelectric sensor, it chops off the spring, and the spring is carried to ABS-01.

- The photoelectric sensor confirms the insertion of next spring and ABS-01 repeats the same processes as above.

Machining of spring and assembly of tip are synchronized.

- Between the two machines, air shooter is the only equipment. You can save trouble and cost.

- As the production speed is controlled to be same in two machines, there is no bottleneck.

As seen above, when ABS-01 and C1-TIP are working together, the effectiveness is superb. Meanwhile, ABS-01 can be used individually, even being separated from C1-TIP.

| Click below images to view Youtube video | |

|

|

| ABS-01 TIP Assembly Machine | Combined with TOSCO C1-TIP coiling machine |

Standard specifications

| Model | TOSCO ABS-01 |

| Number of pallet | 8 (changeable) |

| Number of process | 4 (changeable) |

| Rotary table diameter (mm) | 200 |

| Machine dimensions (LxWxH, mm) | 485 x 540 x 1300 |

| Mass (kg) | 200 |

Main components (for standard 4 processes)

| Rotary table, diameter 200 mm | 1 set |

| Photoelectric sensor (to confirm spring’s insertion) | 1 set |

| Parts feeder (for tip) | 1式 |

| Parts feeder (for plastic pipe) | 1 set |

| Stocker (for assembled parts) | 1 set |

| Column, arm (except hand chuck) | 4 sets |

| Pallet | 8 sets |

| Pneumatic piping | 1 set |

| Control panel & operation panel | 1 set |

Option

| Hand chuck |